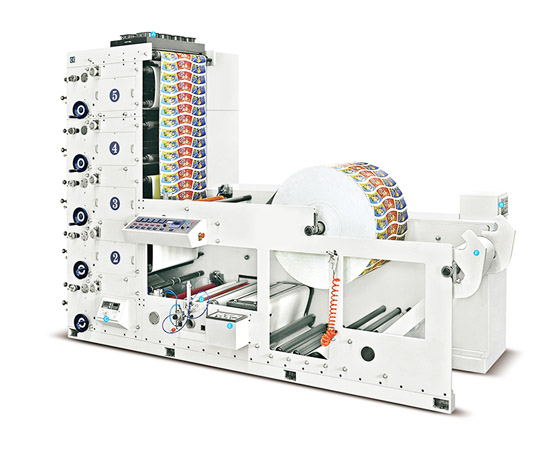

Flexography, also known as flexo printing, is a popular printing technique used in various industries. It involves the use of flexible relief plates made of rubber or photopolymer to transfer ink onto a substrate. This printing method is known for its versatility, speed, and cost-effectiveness, making it a popular choice for many businesses. In this article, we will explore the different products that use flexography and why it is a preferred printing method for these industries.

- Packaging Industry

Flexography is widely used in the packaging industry to print on various substrates such as paper, plastic, and foil. It is commonly used to print on food packaging, beverage cartons, and labels. The printing quality is high, and the ink dries quickly, making it ideal for high-speed production lines. Flexography also allows for the use of a wide range of inks, including water-based, solvent-based, and UV-curable inks.

- Label Industry

Flexography is the preferred printing method for label production due to its ability to print on a wide range of substrates, including pressure-sensitive labels, shrink sleeves, and wraparound labels. It is also ideal for printing variable data, such as barcodes and QR codes, making it a popular choice for product identification and tracking.

- Corrugated Industry

Flexography is widely used in the corrugated industry to print on corrugated cardboard boxes. The printing quality is high, and the ink dries quickly, making it ideal for high-speed production lines. Flexography also allows for the use of a wide range of inks, including water-based, solvent-based, and UV-curable inks.

- Flexible Packaging Industry

Flexography is the preferred printing method for flexible packaging, such as plastic bags, pouches, and films. It is ideal for printing on a wide range of substrates, including polyethylene, polypropylene, and polyester. Flexography also allows for the use of a wide range of inks, including water-based, solvent-based, and UV-curable inks.

- Newspaper Industry

Flexography is used in the newspaper industry to print on newsprint. It is ideal for printing high volumes of newspapers quickly and cost-effectively. Flexography also allows for the use of a wide range of inks, including water-based, solvent-based, and UV-curable inks.

In conclusion, flexography is a versatile printing method that is widely used in various industries. Its ability to print on a wide range of substrates, high-speed production, and cost-effectiveness make it a popular choice for many businesses. Whether it's printing on food packaging, labels, corrugated boxes, flexible packaging, or newspapers, flexography is a reliable and efficient printing method.