Flexographic printing is a popular printing technique that is widely used in various industries, including packaging, labels, and newspapers. One of the critical components of flexographic printing is the ink used in the process. In this article, we will explore the question, "Is flexo ink water-based?" and provide a comprehensive guide to understanding flexographic printing inks.

What is Flexographic Printing?

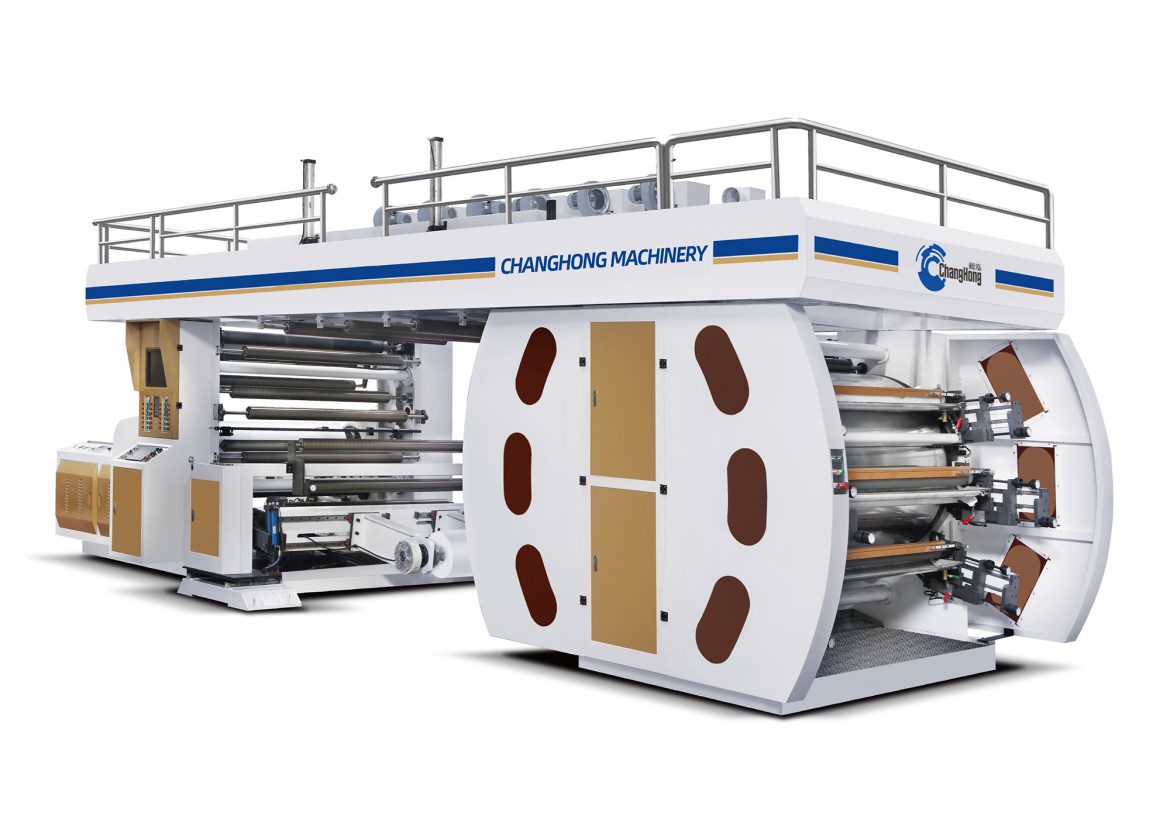

Flexographic printing, also known as flexo printing, is a printing technique that uses flexible relief plates to transfer ink onto a substrate. The plates are made of rubber or photopolymer and are mounted on a rotating cylinder. As the cylinder rotates, the ink is transferred onto the substrate, creating the desired image or text.

Flexographic printing is a versatile printing technique that can be used on a wide range of substrates, including paper, plastic, and metal. It is commonly used in the packaging industry to print on corrugated boxes, bags, and labels.

Types of Flexographic Inks

There are several types of flexographic inks available in the market, including water-based, solvent-based, and UV-curable inks. Each type of ink has its unique properties and is suitable for specific applications.

Water-Based Flexographic Inks

Water-based flexographic inks are made by suspending pigments in water. They are environmentally friendly and do not contain harmful solvents. Water-based inks are commonly used in the food packaging industry as they are safe for direct contact with food.

Water-based inks have several advantages over other types of inks. They dry quickly, have excellent print quality, and are easy to clean up. However, they are not suitable for printing on non-porous substrates such as plastic and metal.

Solvent-Based Flexographic Inks

Solvent-based flexographic inks are made by dissolving pigments in a solvent. They are commonly used in the printing of flexible packaging, labels, and tags. Solvent-based inks have excellent adhesion properties and are suitable for printing on non-porous substrates.

However, solvent-based inks have several disadvantages. They are highly flammable and emit harmful VOCs (volatile organic compounds) during the printing process. They also require special handling and disposal procedures.

UV-Curable Flexographic Inks

UV-curable flexographic inks are cured by exposure to UV light. They are commonly used in the printing of labels, tags, and flexible packaging. UV-curable inks have excellent adhesion properties and are suitable for printing on a wide range of substrates.

However, UV-curable inks have several disadvantages. They require special equipment for curing, and the ink can be expensive. They also emit harmful VOCs during the curing process.

Conclusion

In conclusion, flexographic printing is a versatile printing technique that is widely used in various industries. The type of ink used in the process depends on the application and substrate. Water-based flexographic inks are environmentally friendly and safe for direct contact with food. Solvent-based inks have excellent adhesion properties but emit harmful VOCs. UV-curable inks have excellent adhesion properties but require special equipment for curing.