UV printing on plastic is a cutting-edge technology that has revolutionized the printing industry. It offers a plethora of benefits, including high-quality prints, quick drying times, and the ability to print on a wide range of materials. However, mastering this technique requires a deep understanding of the process, the materials involved, and the equipment used. This blog post aims to provide an in-depth guide on how to UV print on plastic, ensuring high-quality, durable, and vibrant prints.

Understanding UV Printing

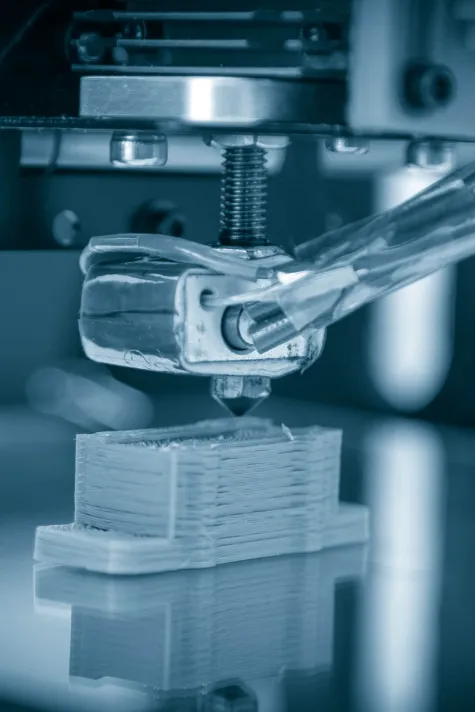

UV printing is a form of digital printing that uses ultraviolet lights to dry or cure ink as it is printed. As the printer distributes ink on the surface of a material (in this case, plastic), specially designed UV lights follow close behind, curing or drying the ink instantly. This process allows for printing on virtually any material, including plastic, without the need for a special coating or treatment.

Choosing the Right Plastic

Not all plastics are created equal when it comes to UV printing. Some plastics may warp or melt under the heat of the UV light, while others may not hold the ink well. It's crucial to choose a plastic that is compatible with UV printing. Acrylics, polycarbonates, and PVC are commonly used due to their durability and excellent ink adhesion.

Preparing the Plastic Surface

Before printing, the plastic surface needs to be properly prepared to ensure optimal ink adhesion. This usually involves cleaning the surface to remove any dust, grease, or other contaminants. Some types of plastic may also require a pre-treatment with a special primer or adhesion promoter to improve ink adhesion.

The UV Printing Process

The UV printing process involves several steps:

- Design Preparation: The design to be printed is created or modified using graphic design software. It's important to ensure the design is high-resolution to achieve a clear, sharp print.

- Printer Setup: The printer is set up with the appropriate settings for the plastic material. This may include adjusting the UV light intensity, print speed, and ink flow.

- Printing: The design is printed onto the plastic surface. The UV lights cure the ink instantly, resulting in a vibrant, durable print.

- Post-Processing: After printing, the plastic may need to be cleaned or coated with a protective layer to enhance the durability of the print.

Conclusion

UV printing on plastic is a versatile and efficient method for producing high-quality prints. However, it requires a thorough understanding of the process, the materials, and the equipment to achieve the best results. With the right knowledge and skills, you can master the art of UV printing on plastic and unlock its full potential.