Circulating Fluidized-Bed(CFB) technology has emerged as a highly efficient and environmentally friendly process used in various industrial applications, including energy generation, chemical processing, and material production. By utilizing the principles of fluidization, CFB technology enhances heat and mass transfer, leading to improved efficiency and reduced emissions. This article explores the key methods and industrial applications of CFB technology, with a focus on the contributions of Chem-Unit Technologies Co. Ltd., a company specializing in modular experimental devices, pilot plants, production units, and robotic systems for industrial applications.

Key Methods in Circulating Fluidized-Bed Technology

1. Fluidization Mechanism

CFB technology operates by suspending fine solid particles in an upward-flowing gas stream, creating a fluid-like state. This fluidization process ensures better contact between gas and solids, leading to enhanced reaction rates and efficient energy utilization. Unlike conventional bubbling fluidized beds, CFB systems achieve higher solids circulation rates and improved mixing, making them ideal for large-scale industrial processes.

2. Particle Separation and Recirculation

One of the defining features of CFB technology is the continuous circulation of solid particles. The process includes a cyclone separator that captures and returns unreacted particles to the reactor, ensuring complete combustion or reaction. This mechanism enhances fuel efficiency and minimizes waste production, making CFB technology a sustainable choice for industries.

3. Heat Recovery and Emission Control

CFB technology incorporates heat recovery mechanisms, such as steam generation and heat exchangers, to improve overall energy efficiency. Additionally, the combustion process occurs at lower temperatures compared to conventional boilers, resulting in significantly reduced nitrogen oxide (NOx) emissions. The use of limestone in CFB reactors also enables in-situ sulfur capture, further reducing sulfur dioxide (SO2) emissions.

Industrial Applications of CFB Technology

1. Power Generation

CFB boilers are widely used in power plants to generate electricity from coal, biomass, and waste-derived fuels. Due to their ability to handle a wide range of fuel types and their low emissions profile, CFB-based power generation is gaining popularity in the energy sector.

2. Chemical Processing

CFB reactors are employed in the production of chemicals such as synthetic fuels, catalysts, and polymers. The high mixing efficiency and uniform temperature distribution in CFB systems ensure optimal reaction conditions, making them suitable for large-scale chemical manufacturing.

3. Metallurgical and Material Processing

The metallurgical industry utilizes CFB technology for roasting, calcination, and other high-temperature material processing applications. The efficient heat transfer and controlled reaction environment in CFB reactors enable the production of high-purity materials with minimal energy consumption.

4. Waste Treatment and Environmental Applications

CFB technology plays a crucial role in waste-to-energy (WTE) applications, where municipal solid waste and industrial by-products are converted into valuable energy sources. The ability of CFB systems to handle diverse feedstocks and their excellent emission control capabilities make them an ideal choice for sustainable waste management.

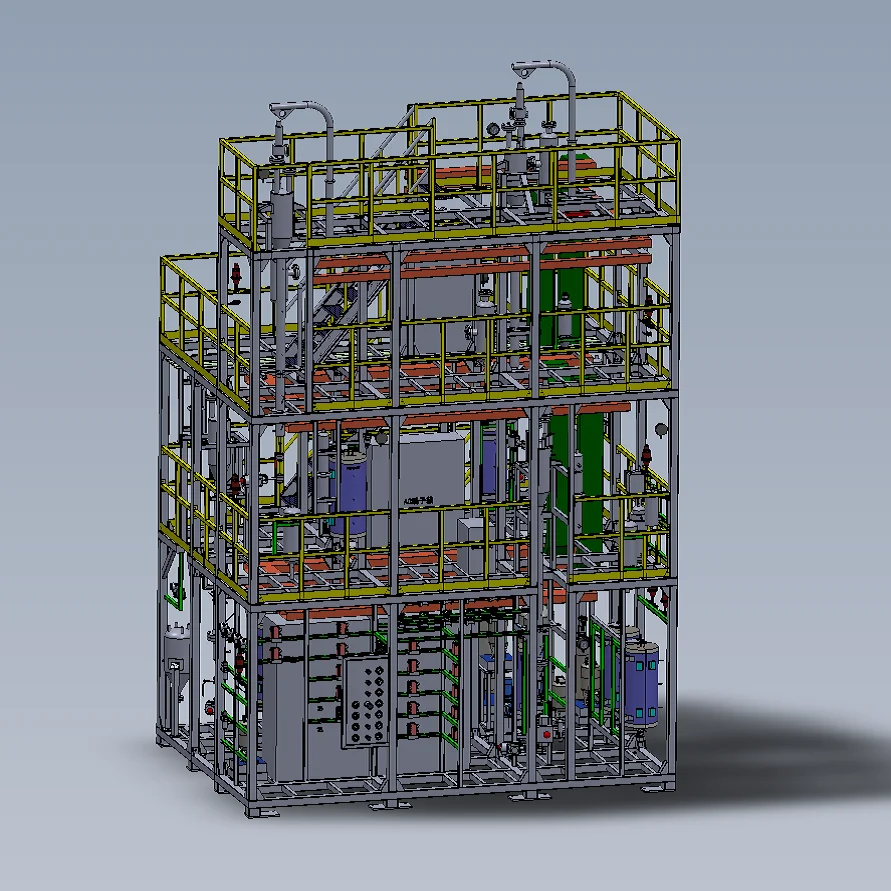

Chem-Unit: CFB Solutions

Chem-Unit Technologies Co. Ltd. is a leading company specializing in the research, design, manufacturing, and technical services of modular experimental devices, pilot plants, production units, and robotic systems for industrial applications. The company offers customized solutions for CFB-based experimental and production setups, catering to industries seeking innovative and efficient fluidized-bed technologies.

With a focus on automation and digitalization, Chem-Unit Technologies integrates cutting-edge control systems and robotic solutions into their CFB units, enhancing precision and operational efficiency. Their expertise in process optimization and system integration makes them a trusted partner for companies looking to implement CFB technology in their industrial operations.

Conclusion

Circulating Fluidized-Bed technology has revolutionized various industrial sectors by offering a highly efficient and environmentally friendly solution for energy generation, chemical processing, and material production. With companies Chem-Unit Technologies Co. Ltd. at the forefront of innovation, CFB technology continues to evolve, driving industrial progress and sustainability. Whether in power generation, waste treatment, or chemical production, CFB systems provide a versatile and reliable approach to modern industrial challenges.

Exploring the Role of Circulating Fluidized-Bed Units in the Chemical and Petrochemical Industries

en.chem-unit.com

Shanghai Chem-Unit Technologies Co. Ltd