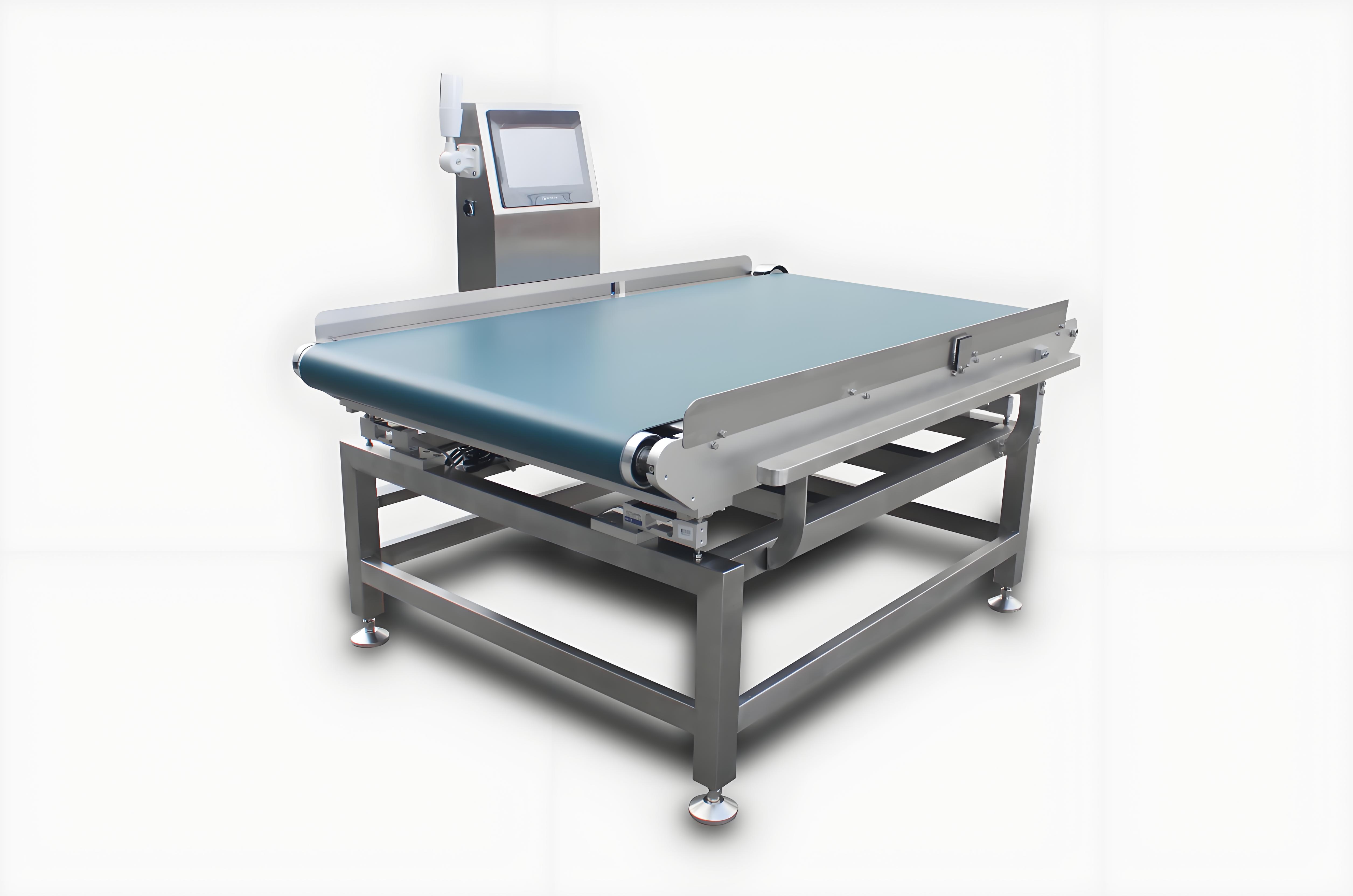

In today's fast-paced manufacturing world, automation is no longer a luxury—it's a necessity. As companies strive to improve accuracy, reduce waste, and meet increasingly strict quality control standards, one piece of equipment has become especially critical: the conveyor weight checker, also known as an in-line checkweigher. This smart solution plays a vital role in ensuring product consistency and optimizing operational efficiency across a wide range of industries.

Here are the top 5 benefits of integrating conveyor weight checkers into your automated production line:

1. Ensure Product Weight Accuracy and Compliance

Conveyor weight checkers are designed to automatically weigh every product in real-time as it moves along the production line. This ensures that every package meets the target weight within a pre-set tolerance. For industries such as food, pharmaceuticals, and chemicals—where regulatory compliance is mandatory—accurate weight control helps avoid costly fines, recalls, and reputation damage.

2. Reduce Waste and Material Overfill

By identifying and eliminating overfilled products, weight checkers help companies reduce unnecessary material usage. This not only lowers production costs but also contributes to sustainability by minimizing waste. Conversely, underfilled products can be rejected to maintain brand integrity and customer satisfaction.

3. Improve Production Efficiency

Conveyor weight checkers are seamlessly integrated into automated systems, allowing for non-stop operation without human intervention. Faulty items are automatically rejected, and real-time feedback helps optimize upstream filling processes. The result: increased line speed, fewer bottlenecks, and reduced downtime.

4. Enable Quality Control and Data Tracking

Modern weight checkers come equipped with advanced software and data logging capabilities. They collect and analyze data on each product’s weight, which helps detect process fluctuations and quality trends over time. This makes it easier to implement predictive maintenance, troubleshoot issues quickly, and ensure continuous improvement.

5. Enhance Brand Trust and Customer Satisfaction

In a market where consumers demand consistency, conveyor weight checkers help maintain uniform product quality. Accurate and reliable weight measurements reduce the risk of customer complaints due to over- or under-filled packages. In turn, this supports brand loyalty and long-term business growth.

Why Choose Dostar Packing Equipment Co., Ltd?

As a high-tech enterprise specializing in automated packaging systems, Dostar Packing Equipment Co., Ltd has been a trusted partner for companies seeking to modernize their production lines. With years of experience in the R&D, integration, manufacturing, and servicing of automated and semi-automated packaging systems, Dostar offers tailor-made solutions that meet the evolving needs of its clients.

Whether you're building a new fully automated line or upgrading an existing semi-automated system, Dostar provides:

-

Custom-integrated conveyor weight checking systems

-

Turnkey automatic packaging lines

-

Expert technical support and after-sales service

By leveraging cutting-edge technology and industry expertise, Dostar helps manufacturers across sectors improve productivity, maintain quality, and stay competitive in a demanding marketplace.

Conclusion

Incorporating conveyor weight checkers into your production line is a smart move for any business aiming for precision, efficiency, and quality. With trusted partners like Dostar Packing Equipment Co., Ltd, implementing such advanced automation tools becomes not only feasible but transformational.

www.dostar-pack.com

Dostar Packing Equipment (Wuxi) Co., Ltd