Circular connectors play a foundational role in modern electronic and electromechanical systems. Their robust geometry, proven locking mechanisms, and wide range of configuration options make them indispensable across industries that demand reliability, durability, and consistent performance. From industrial automation and transportation to renewable energy and defense systems, circular connectors are often the critical interface that keeps high-value equipment operating under challenging conditions.

Yet, as applications become more complex and environments more demanding, choosing the right circular connector is no longer just a matter of pin count or shell size. Engineers must consider standards compliance, sealing performance, material selection, and long-term maintainability. This guide breaks down the essentials, providing a practical reference for engineers, integrators, and technical buyers. It also highlights how companies like Dconntek, a leading designer and assembler of custom-engineered connectors and cable solutions, support industries that cannot compromise on reliability.

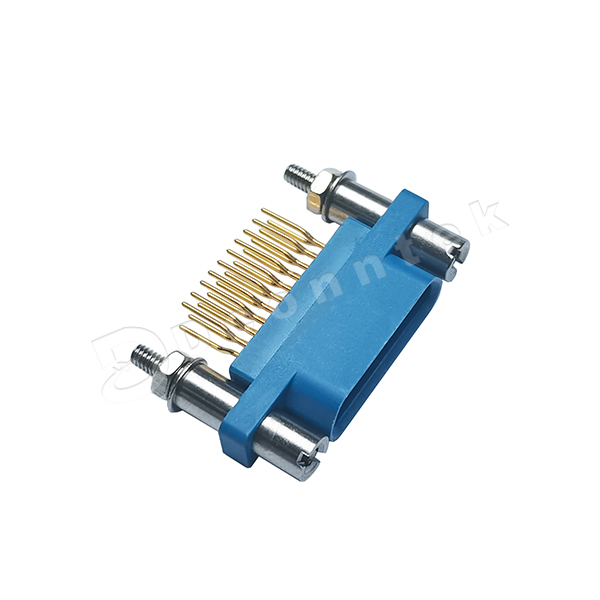

What Are Circular Connectors?

Circular connectors are multi-pin electrical connectors with a cylindrical housing designed for secure mating and long-term durability. Their geometry offers natural resistance to mechanical stress and environmental exposure. Most circular connectors are equipped with threaded, bayonet, or push-pull locking mechanisms to maintain a secure electrical connection even under vibration, shock, or repeated handling.

Key advantages include:

Efficient use of space with high pin density.

Strong mechanical stability.

Broad compatibility with sealing, grounding, and shielding options.

Easy mating and unmating, often with tactile confirmation.

These characteristics explain why circular connectors remain widely used even as rectangular and micro-form-factor connectors gain popularity in specific applications.

Common Types of Circular Connectors

Choosing the right type depends on electrical, mechanical, and environmental requirements. Below are the most widely used categories.

1. Industrial Circular Connectors

These connectors are commonly used in machinery, robotics, automation, sensors, actuators, power distribution modules, and outdoor equipment. They often follow standardized coding systems such as M8, M12, M16, and M23.

Key characteristics:

High resistance to shock and vibration.

IP-rated sealing for dust and water protection.

Availability in power, signal, and hybrid configurations.

Engineers choose industrial circular connectors when they need connectors capable of surviving daily operational stress while ensuring signal integrity.

2. Military and Aerospace Circular Connectors

Designed according to MIL-DTL specifications, these connectors are engineered for extreme durability. They are used in avionics, ground vehicles, radar systems, satellite equipment, and mission-critical communication systems.

Typical requirements:

Corrosion-resistant materials.

Strict mechanical tolerances.

EMI/RFI protection.

High thermal stability.

Although these connectors are more specialized, many commercial applications also adopt MIL-spec connectors when they require long-term reliability and proven performance.

3. Push-Pull Circular Connectors

Push-pull connectors are ideal for medical devices, test and measurement equipment, and compact field instrumentation. Their quick-mating mechanism ensures intuitive operation while maintaining strong retention.

Core benefits:

High mating cycle durability.

Secure locking without the need for threaded coupling.

Compact designs optimized for handheld devices.

Push-pull connectors are increasingly selected for next-generation diagnostic equipment and wearable industrial tools where downtime and connector damage must be minimized.

4. Power Circular Connectors

These connectors are designed to handle high-current transmission safely. They are widely used in battery systems, e-mobility platforms, industrial drives, and renewable-energy converter equipment.

Typical features:

High-current contacts with reinforced insulation.

Flame-retardant materials.

Robust keying to prevent mis-mating.

Optional touch-proof designs.

Power circular connectors must be selected carefully, as thermal management and long-term conductivity are essential for equipment safety.

5. Data and Signal Circular Connectors

With the rise of IIoT and high-speed networking, circular connectors designed for data transmission have gained importance. Modern versions support protocols such as Ethernet, CAN, USB, and even fiber-optic communication.

Notable aspects:

Low-loss signal paths.

Enhanced shielding against electrical noise.

Options for hybrid connectors combining power and data.

Such connectors are frequently used in distributed sensor networks and ruggedized communication systems.

Major Standards That Govern Circular Connectors

Circular connectors are widely standardized to ensure compatibility, performance, and safety across industries. Understanding these standards is important for selecting the right product.

IP Ratings

The Ingress Protection (IP) rating defines resistance to dust and water. Industrial circular connectors commonly range from IP65 to IP69K, depending on application needs. For outdoor applications or washdown environments, IP67 or above is often recommended.

IEC and DIN Standards

Many civilian connectors comply with IEC 61076-2 standards, which define performance criteria for M-series connectors. These standards ensure consistency in coding, thread size, pin layout, and mechanical durability.

MIL-Spec Standards

MIL-DTL-5015, MIL-DTL-38999, and related specifications define rugged circular connectors used in military and aerospace programs. These standards cover materials, coupling mechanisms, plating, temperature performance, and vibration resistance.

UL and CSA Certifications

For North American products, compliance with UL 1977 or CSA C22 standards is often required. These certifications indicate that connectors meet safety and performance benchmarks relevant to industrial and commercial applications.

Understanding these standards ensures that connectors can be confidently integrated into regulated equipment designs.

Applications Across Industries

Circular connectors are used in an exceptionally broad range of industries. Their versatility is one of the reasons they remain a preferred solution for mechanical engineers and system integrators.

Industrial Automation

Robots, conveyors, vision systems, and programmable controllers rely heavily on circular connectors for signal, power, and data transfer. M12 and M8 connectors are especially common in sensor and actuator networks.

Transportation and Mobility

Rail, marine, heavy vehicles, and electric mobility platforms use circular connectors that withstand vibration, moisture, and temperature fluctuations.

Renewable Energy

Wind turbines, solar inverters, battery-energy storage systems, and grid-tie equipment require connectors that can operate in harsh, outdoor conditions for long periods.

Medical Equipment

Push-pull connectors provide secure and hygienic interfaces for diagnostic devices, surgical tools, and patient-monitoring equipment.

Defense and Aerospace

MIL-spec circular connectors support avionics, communication systems, mission-critical sensors, and rugged ground hardware.

Across all these sectors, engineering teams value circular connectors because they provide predictable, repeatable performance in applications that cannot tolerate failure.

Custom-Engineered Circular Connector Solutions

While standardized connectors meet many needs, advanced applications often require tailored designs for environmental sealing, material compatibility, uncommon pin layouts, or hybrid signal/power requirements.

This is where specialized engineering partners such as Dconntek play a critical role. Dconntek is a leading designer and assembler of custom-engineered connectors and cable solutions built for harsh environments. By working closely with customers to understand electrical, mechanical, and regulatory constraints, Dconntek develops solutions that fit real-world requirements rather than forcing compromises with off-the-shelf products. Their ability to maintain high standards of delivery speed, service quality, and production stability makes them a trusted partner across demanding industries.

For organizations seeking rugged, application-specific circular connectors, Dconntek offers a comprehensive portfolio, including fully customized solutions. More details can be found through their dedicated circular connector page: <a href="https://www.dconntek.com/Circular-Connector">circular connectors</a>.

How to Choose the Right Circular Connector

Selecting the correct connector involves evaluating environmental, electrical, and mechanical requirements.

Consider Environmental Conditions

Temperature range, exposure to chemicals, outdoor usage, and vibration levels all influence connector selection. High-sealing connectors may be required for wet or dusty environments.

Evaluate Electrical Requirements

Key parameters include current rating, operating voltage, shielding performance, and contact resistance. Hybrid connectors may simplify wiring by combining functions in one interface.

Check Mechanical and Mating Requirements

Factors such as locking mechanisms, mating cycle durability, and assembly methods must align with operational needs.

Review Standards and Certifications

Regulated industries may require UL-listed or MIL-DTL-compliant connectors.

Assess Availability and Long-Term Support

Working with experienced manufacturers helps ensure reliable sourcing, technical guidance, and lifecycle stability.

Conclusion

Circular connectors remain indispensable components in modern equipment architecture. Their mechanical strength, wide configurability, and proven environmental resilience make them ideal for industrial, military, medical, and transportation applications. With growing system complexity, many projects now depend on specialized engineering support to develop connectors tailored to real-world operating requirements. By offering custom-engineered solutions and close collaboration with customers, companies like Dconntek help ensure that equipment operates reliably even in the toughest conditions.

Whether a project requires standard industrial M-series connectors or fully customized assemblies for harsh environments, understanding the fundamentals outlined in this guide will help engineers make informed decisions and achieve long-term system reliability.

www.dconntek.com

Dconntek