In modern mechanical systems, GT pulleys (also known as GT timing pulleys) are essential components that ensure precise power transmission, efficient operation, and long-term reliability. Selecting the right GT pulley for your system can significantly impact performance, reduce wear and tear, and optimize maintenance cycles.

This article provides a comprehensive guide on how to choose the right GT pulley, with insights from Hetuoda Machinery Manufacturing, a leading provider of high-precision transmission components, including timing pulleys, racks, tensioners, gears, and custom-machined parts, along with OEM services tailored to client specifications.

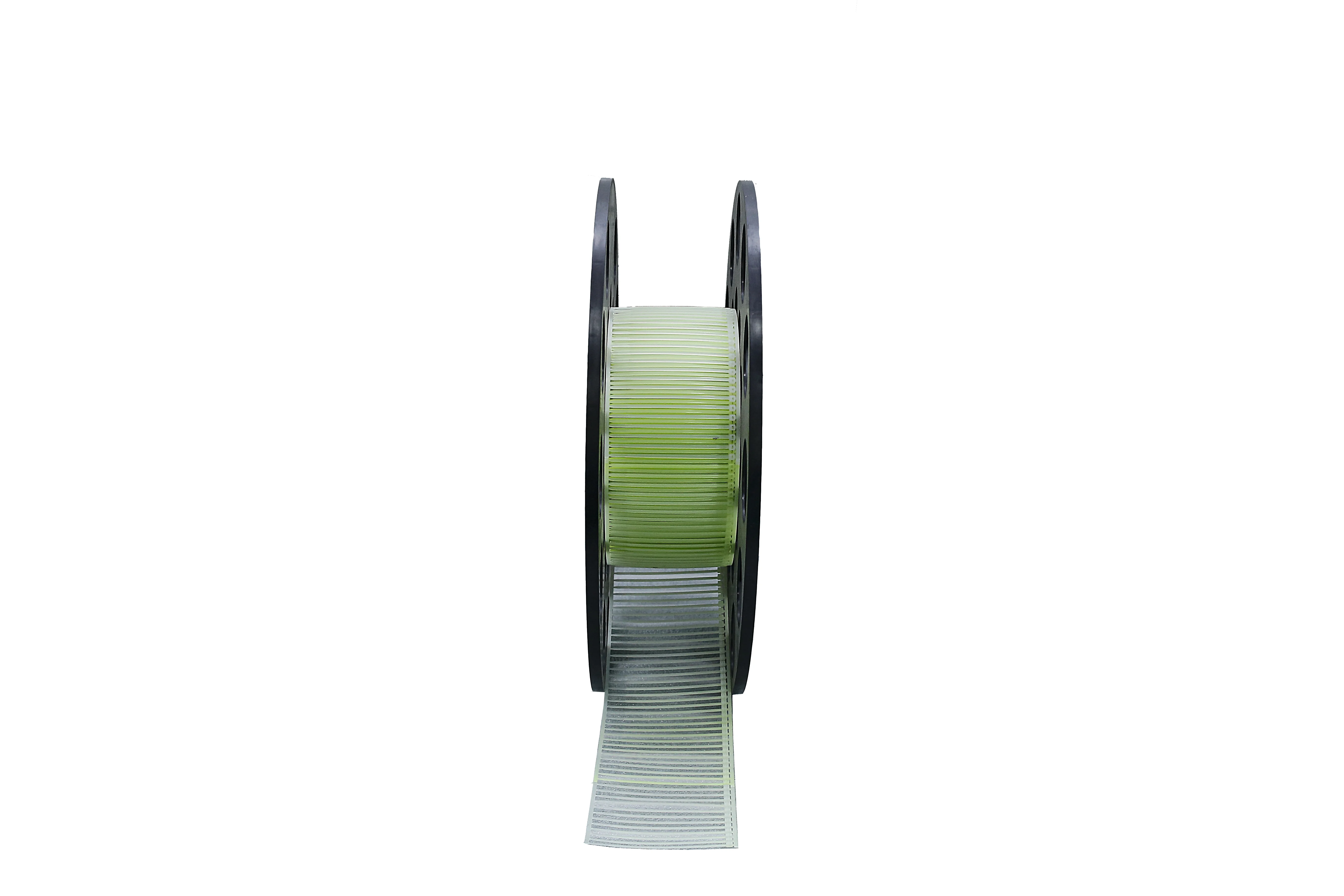

What Is a GT Pulley?

A GT pulley is a type of timing pulley specifically designed for use with GT (Gates Tooth) timing belts. It features curved tooth profiles that match GT belts, ensuring:

-

High power transmission efficiency

-

Minimal backlash and slippage

-

Reduced noise and vibration

-

Extended belt and pulley lifespan

GT pulleys are widely used in automation, robotics, automotive engines, conveyor systems, and industrial machinery.

Factors to Consider When Choosing a GT Pulley

1. Pulley Material

GT pulleys are typically made from aluminum, steel, or high-strength plastic. Your choice should depend on:

-

Load requirements: Steel pulleys handle heavy loads better, while aluminum is lightweight and corrosion-resistant.

-

Environment: For corrosive or outdoor environments, anodized aluminum or coated steel is ideal.

Hetuoda Machinery Manufacturing provides a variety of high-precision materials to meet both standard and custom requirements.

2. Pulley Size and Pitch

-

Pitch: Ensure the GT pulley tooth pitch matches the belt’s pitch (e.g., 2mm, 3mm, 5mm, etc.) for proper engagement.

-

Diameter: Larger pulley diameters reduce bending stress on the belt and increase transmission efficiency.

-

Width: Pulley width should accommodate the belt width to avoid misalignment and premature wear.

3. Number of Teeth

The number of teeth affects:

-

Transmission ratio

-

Torque capacity

-

Belt engagement and longevity

A correctly selected tooth count ensures smooth operation and minimizes backlash, which is critical in high-precision machinery.

4. Bore Size and Keyway

-

Ensure the pulley bore matches the shaft diameter.

-

Check for keyways, set screws, or custom fittings for secure installation.

Hetuoda Machinery Manufacturing offers OEM services for custom bore sizes and mechanical adaptations, allowing pulleys to fit specific shafts perfectly.

5. Application Environment

Consider factors such as:

-

Operating speed and torque

-

Temperature range

-

Presence of dust, oil, or chemicals

High-quality GT pulleys are designed to maintain performance under demanding industrial conditions, minimizing downtime and maintenance costs.

6. Maintenance and Durability

-

Opt for pulleys with precision-machined teeth for consistent engagement and long-term reliability.

-

Regular inspection and proper alignment of GT pulleys can extend belt and component life.

Hetuoda Machinery Manufacturing emphasizes precision machining and quality control to ensure pulleys maintain performance over thousands of operating hours.

Why Choose Hetuoda Machinery Manufacturing for GT Pulleys

Hetuoda Machinery Manufacturing specializes in high-precision transmission components, including:

-

Timing pulleys (GT, HTD, T5, T10, etc.)

-

Gear racks and gears

-

Tensioners and other precision machined parts

Key advantages:

-

OEM services to produce custom pulleys tailored to your system specifications

-

High-quality materials and precision machining for industrial reliability

-

Expertise in various applications including automation, robotics, automotive, and heavy machinery

By partnering with Hetuoda, engineers and technicians can ensure optimal performance, precise power transmission, and long-lasting components for their mechanical systems.

Conclusion

Choosing the right GT pulley requires careful consideration of material, size, pitch, number of teeth, bore compatibility, application environment, and maintenance needs. A properly selected GT pulley improves efficiency, reduces wear, and ensures smooth operation of mechanical systems.

With reliable suppliers like Hetuoda Machinery Manufacturing, you gain access to high-precision, customizable GT pulleys and transmission components that meet the demanding requirements of modern industrial and automotive applications. Investing in quality pulleys ensures optimal performance and longevity for your mechanical systems.

www.cdepulley.com

Suzhou Hetuoda Machinery Manufacturing Co., Ltd.