High-quality gears are critical components in industries ranging from automotive and motorcycles to industrial pumps, reducers, and timing pulleys. Achieving precision, surface finish, and consistency in gear production requires advanced machinery—and nothing is more essential than the right CNC gear grinder.

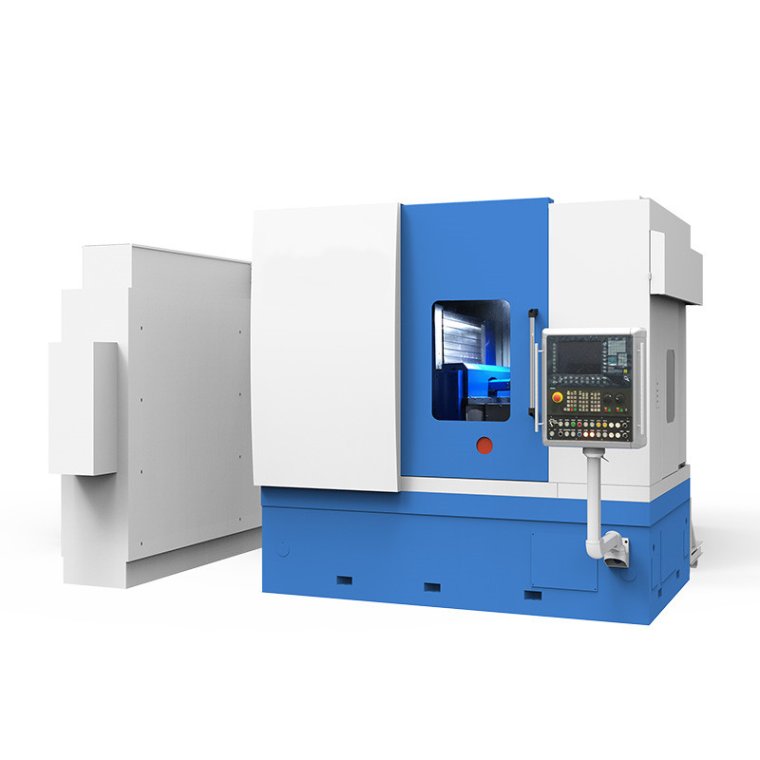

Selecting the proper machine affects productivity, gear quality, and overall manufacturing efficiency. GLT Machinery (GLTM/GLT), a leading CNC gear grinding machine manufacturer in China, specializes in high-speed, high-efficiency CNC gear grinders designed for high rigidity, reliability, and precision. In this article, we explore key considerations for choosing a CNC gear grinder and how GLT’s solutions support optimal gear production.

1. Understanding Your Gear Production Needs

The first step in selecting a CNC gear grinder is to clearly define the requirements of your gear production process. Consider:

-

Gear type and application: Spur gears, helical gears, bevel gears, worm gears, or pulleys

-

Material: Steel, alloy, or other metal compositions

-

Batch size and production volume: Small batches require flexible setups, while mass production benefits from automated high-speed grinders

-

Accuracy and surface finish requirements: Class 5–8 accuracy or finer tolerances, depending on the application

Understanding these factors will guide you toward a machine that can meet your specific production goals.

2. Key Features to Look for in a CNC Gear Grinder

Choosing the right CNC gear grinder involves assessing the machine’s capabilities in terms of precision, efficiency, and durability.

High Rigidity and Stability

Gear grinding demands consistent accuracy under high-speed operation. Look for machines built with:

-

Heavy-duty castings

-

Rigid structural frames

-

Vibration-damping designs

GLT CNC gear grinders are engineered with high rigidity to maintain dimensional accuracy and surface finish even under demanding production loads.

Precision Motion Systems

A CNC gear grinder must offer precise positioning and smooth motion control:

-

High-precision linear guides and ball screws

-

Advanced servo motors for controlled feed rates

-

CNC control systems with adaptive grinding programs

These features ensure uniform material removal and minimize tooth profile deviations.

High-Efficiency Grinding

Efficiency is key in modern production. Consider:

-

High-speed spindle designs

-

Optimized grinding wheel selection and dressing

-

Automated loading/unloading for continuous operation

GLT machines provide high-speed and efficient grinding cycles, significantly reducing production time without compromising quality.

User-Friendly CNC Controls

Modern CNC gear grinders should include:

-

Intuitive software interfaces

-

Customizable grinding programs

-

Real-time monitoring and error diagnostics

These features simplify operations, reduce operator training time, and improve repeatability.

3. Matching Machine Specifications to Production Requirements

When evaluating CNC gear grinders, consider:

-

Workpiece size: Maximum gear diameter and face width supported

-

Tooth profile capability: Ability to grind involute, straight, or helical gears

-

Grinding wheel compatibility: Different wheel materials (aluminum oxide, CBN, etc.) for various gear materials

-

Automation options: Pallet changers, robotic loaders, or integration with production lines

Selecting a machine that aligns with your production requirements ensures consistent quality and optimal utilization of your investment.

4. Maintenance and Reliability Considerations

A reliable CNC gear grinder minimizes downtime and protects production schedules. Key factors include:

-

Quality of components: High-precision linear guides, motors, and CNC controls

-

Durable construction: Cast iron or steel frames to resist wear and deformation

-

Ease of maintenance: Accessible components, automatic lubrication, and diagnostic tools

GLT Machinery designs all CNC gear grinders for long-term reliability, providing clients with machines that maintain accuracy and performance over years of production.

5. Why Choose GLT Machinery CNC Gear Grinders

GLT Machinery has extensive experience delivering gear production solutions to industries including automotive, motorcycles, reducers, timing pulleys, and pumps. Their machines stand out due to:

-

High rigidity: Ensures dimensional stability and accurate gear profiles

-

High efficiency: Faster cycle times without sacrificing quality

-

High reliability: Durable components designed for long-term operation

-

Customizable solutions: Tailored to meet specific gear sizes, profiles, and production volumes

By combining advanced engineering with practical application experience, GLT provides complete gear grinding solutions for manufacturers seeking quality, efficiency, and reliability.

6. Conclusion

Choosing the right CNC gear grinder is essential for producing high-quality gears consistently and efficiently. Consider your gear types, production volume, accuracy requirements, and operational efficiency when evaluating machines. Look for features such as high rigidity, precise motion control, advanced CNC software, and durable construction to ensure long-term success.

GLT Machinery (GLTM/GLT) offers high-speed, high-efficiency CNC gear grinders that deliver precision, productivity, and reliability. For manufacturers in automotive, industrial reducers, pumps, or other gear-dependent industries, GLT’s solutions provide a trusted foundation for achieving superior gear quality and production performance.

www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT)