As a core link in petroleum processing, oil refineries involve complex processes, harsh operating conditions, and large quantities of flammable and explosive petroleum products and chemicals. Safe production in oil refineries has always been a focus of industry attention. In recent years, although refining technology has been continuously upgraded, safety accidents caused by improper operation, equipment failure, or management negligence still occur frequently, with explosions being particularly serious, posing a significant threat to personnel safety, equipment integrity, and environmental protection. Against this backdrop, valve interlocking systems, as an effective safety control measure, have gradually been widely adopted in oil refineries. This article will analyze in depth the working mechanism, application scenarios, and key role of valve interlocking systems in preventing refinery explosions.

1. Main Causes of Refinery Explosions

To understand how valve interlocking systems prevent explosions, it is essential to first understand the main causes of refinery explosions. Oil refineries involve numerous processes, including crude oil distillation, catalytic cracking, hydrorefining, and aromatics separation, each with potential hazards. The main causes include:

Leakage of flammable and explosive media: Most raw materials, semi-finished products, and finished products involved in oil refining are highly flammable, such as light hydrocarbons, liquefied petroleum gas (LPG), benzene, and toluene. Once pipelines, valves, or containers leak, they can form explosive mixtures with air, posing an explosion risk.

High-temperature and high-pressure operating conditions: Oil refining processes typically operate under high-temperature and high-pressure conditions. Equipment failure or improper operation can easily lead to gas leaks, overheating reactions, or even pipeline ruptures, triggering explosions.

Process operation errors: Oil refining processes are complex and require a high level of expertise from operators. Operational errors during production line switching, equipment start-up and shutdown, or maintenance can cause abnormal material mixing, creating an explosive environment.

Static electricity and ignition sources: Liquid transportation, spraying operations, and gas flow in oil refining plants are prone to generating static electricity. If pipeline grounding is inadequate or protective measures are insufficient, exposure to open flames or sparks can easily ignite an explosion.

The combination of these factors makes oil refining plants extremely high-risk. Effectively preventing explosions has become a crucial issue in safety management.

2. Working Principle of Valve Interlock Devices

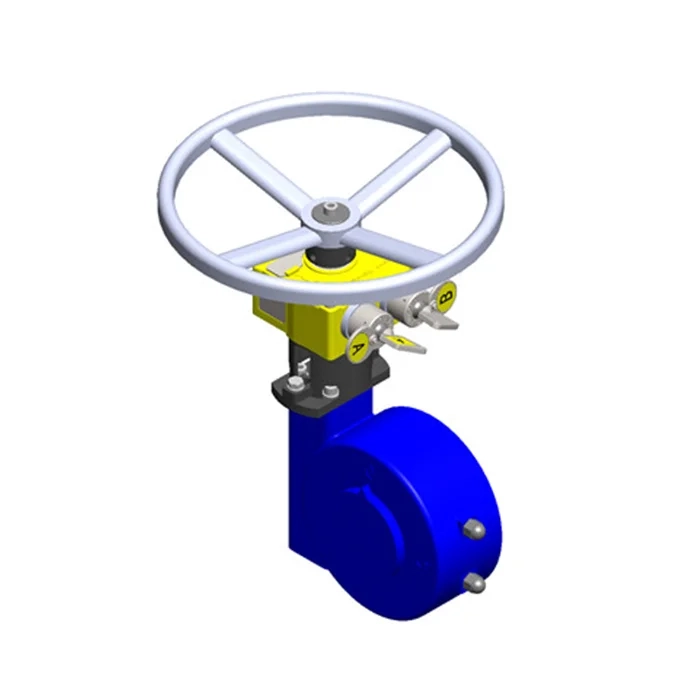

Valve interlock devices are mechanized safety control systems designed to ensure that operators strictly follow predetermined safety procedures when operating pressure safety valves. This system uses a uniquely coded key to physically constrain each operational step, preventing potential misoperation or dangerous operations.

The core concept of valve interlock systems is "misoperation prevention," ensuring that even if an operator is inexperienced or makes a mistake, it will not endanger the production system. In this way, the system forms the first line of defense before potential hazards occur.

3. The Key Role of Valve Interlock Systems in Explosion Protection

Preventing Explosions Caused by Operational Errors

In refineries, operators may misoperate valves due to inexperience or in emergency situations, leading to abnormal mixing of flammable gases or a sudden pressure surge. Valve interlock systems restrict the operational sequence through preset logic. For example, a steam valve cannot be opened until the fuel supply valve is closed, effectively preventing explosions caused by improper operation.

Avoiding Abnormal Media Mixing

In chemical and refining processes, there are strict requirements for temperature, pressure, and flow rate when mixing different materials. Valve interlock systems ensure that material mixing only occurs under safe conditions, preventing abnormal reactions. For example, in an isomerization reactor, if the interlock system detects that the catalyst is not in place or the feed valve is not closed, the system will logically lock to prevent the feedstock from entering the reactor.

Improving the Traceability of Safety Management

The valve interlock system can record the status, time, and executor of each operation, forming a complete operation log. This not only facilitates accident analysis and accountability but also guides training and optimizes operating procedures, fundamentally reducing accident risks.

4. Typical Application Scenarios

Crude Oil Distillation Tower

Crude oil distillation towers involve high-temperature and high-pressure operations, and the gases inside the tower are flammable and explosive. The valve interlock system ensures that the cooling water valve, feed valve, and steam valve operate in the correct sequence, preventing operational errors that could lead to a sudden pressure surge or explosion within the tower.

Hydrorefining Unit

Hydrore reactors operate under harsh conditions, with strict requirements on hydrogen pressure, temperature, and catalyst position. The valve interlock system ensures that reactor valves cannot be opened before a stable hydrogen supply is achieved, preventing hydrogen leakage and potential explosions.

Tank Storage Area Transportation System

Feed transportation in tank storage areas involves multiple pipelines and pump stations. Valve interlocking systems prevent cross-flow of liquids between different storage tanks and logically shut off delivery valves upon detecting abnormal pressure or leakage, ensuring tank safety.

5. Key Implementation Points of Valve Interlocking Systems

Rational Design of Interlocking Logic: When designing a valve interlocking system, a thorough analysis of the process flow and safety risks is necessary to determine the valve operation sequence and key points for precise control.

Regular Inspection and Testing: The interlocking system requires regular inspection to ensure proper response in critical moments.

Operational Training: Operators must be familiar with the functions and operating rules of the valve interlocking system to ensure correct response in abnormal situations.

Integration with Safety Instrumented Systems (SIS): Integrating the valve interlocking system with a Safety Instrumented System (SIS) creates multi-layered protection, improving the overall safety level of the refinery.

6. Conclusion

Refinery explosions often cause incalculable casualties and economic losses. Valve interlocking systems, through scientific logic control and intelligent management, achieve precise constraints on critical valve operations and automatic handling of anomalies, reducing explosion risks at the source. With the development of automation technology, valve interlocking systems will gradually evolve towards digitalization, remote monitoring, and intelligence, providing a more robust guarantee for the safe production of refineries. For every refinery, installing a valve interlocking system is not only about protecting equipment and personnel, but also a crucial commitment to the company's long-term sustainable development.

Nudango, as a valve interlocking system company, is dedicated to providing advanced valve interlocking solutions for high-risk industrial environments such as refineries. The valve interlocking devices developed by the company effectively prevent operational errors and dangerous accidents, reducing the risk of explosion at the source, ensuring production safety and employee safety, while simultaneously improving the overall operational efficiency and management level of refineries.

www.nudango.com

nudango