An automobile steering gear is a core component of the vehicle’s steering system, responsible for translating the driver’s input at the steering wheel into precise movement of the wheels. As a precision mechanical part, it ensures that the steering process is smooth, accurate, and reliable under diverse driving conditions. Its design and quality directly affect driving safety, comfort, and vehicle handling performance.

Modern automobiles increasingly rely on high-precision steering gear systems to support advanced steering technologies, from power-assisted steering to fully electronic steering controls. In this blog post, Longruifa, a professional high precision gear manufacturing factory, will share the structural features of automobile steering gear for sale, its functional role, etc.

Structural Features of Automobile Steering Gear

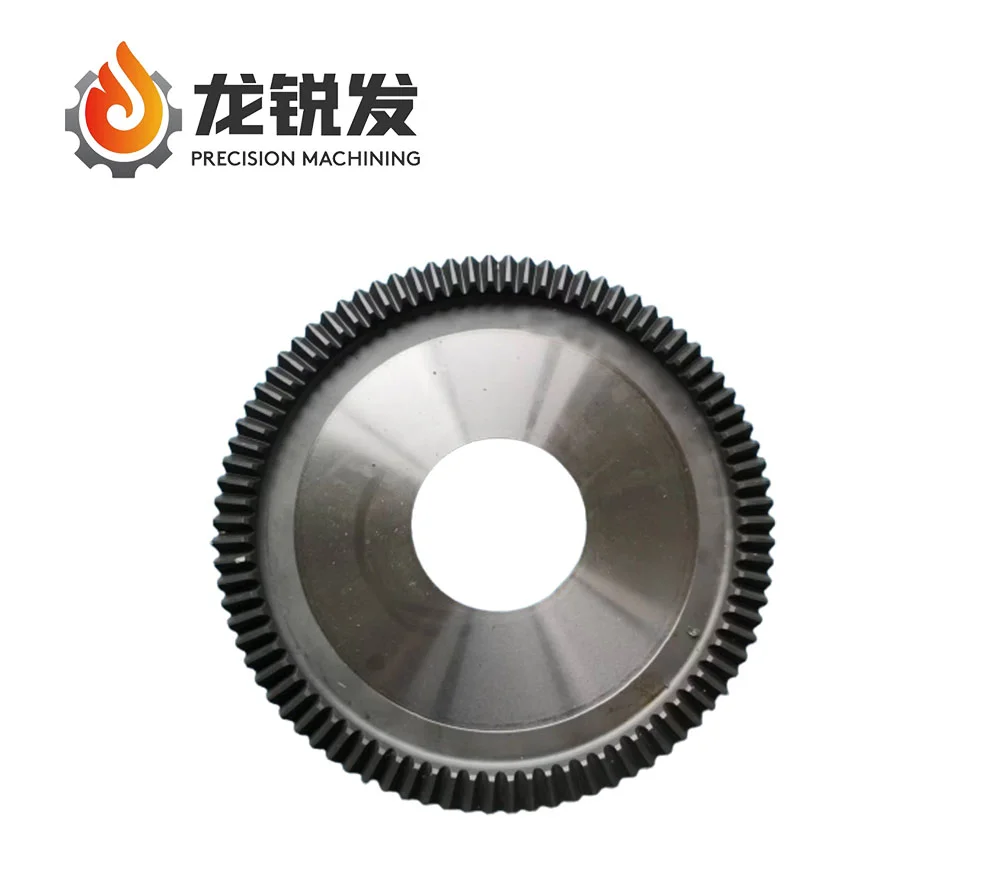

The structure of steering gear determines its operational reliability and efficiency. Typically, steering gears are disc-shaped with a central circular hole, designed for secure attachment to the steering column. Along the disc edges, spiral teeth are precisely spaced, allowing smooth engagement with corresponding gears within the steering assembly.

Materials used in manufacturing are usually high-strength metals with excellent wear resistance. Precision machining ensures that each tooth, groove, and surface is finely finished, minimizing friction and extending the component’s service life. These structural details are critical, as even minor imperfections can compromise steering accuracy and vehicle control.

Types of Steering Gear in Vehicles

Automobile steering gear systems vary depending on the steering mechanism and vehicle design. The most common types include:

-

Rack and Pinion Steering Gear: Uses a circular pinion gear that meshes with a linear rack. This type is favored for passenger cars due to its simplicity, light weight, and responsive handling.

-

Recirculating Ball Steering Gear: Employs ball bearings within a worm gear assembly to reduce friction and provide smooth operation. Common in trucks and larger vehicles.

-

Electric Power Steering Gear: Integrates sensors and electric actuators to assist or fully control steering without hydraulic systems. Increasingly used in modern electric vehicles.

Each type of steering gear balances factors such as precision, mechanical complexity, cost, and durability to suit specific vehicle requirements.

Functional Role of Automobile Steering Gear

The primary function of a steering gear is to convert rotational motion from the steering wheel into lateral motion of the wheels. This involves coordinating multiple components, such as the steering column, pinion, rack, and tie rods. By accurately meshing gears, the system ensures that the driver’s input results in precise steering angles, essential for safe vehicle navigation.

In addition to directional control, steering gear systems play a crucial role in absorbing driving forces from the road. The component must withstand torsional stress, vibration, and wear, maintaining consistent performance over long-term operation. Its mechanical integrity directly affects vehicle stability and driver confidence.

Material Considerations in Steering Gear Manufacturing

High-quality automobile steering gear components require metals with exceptional strength, toughness, and resistance to fatigue. Commonly used materials include alloy steels, heat-treated metals, and surface-hardened steel for the gear teeth.

The manufacturing process often involves precision CNC machining, grinding, and surface finishing to achieve tolerances as tight as ±0.05 mm. Such precision minimizes backlash and ensures smooth gear engagement, reducing noise and improving overall steering responsiveness.

Innovations in Steering Gear Design

Recent developments in steering gear technology focus on improving performance, efficiency, and adaptability. Key innovations include:

-

Compact Gear Geometry: Reduces weight while maintaining structural strength, contributing to fuel efficiency and vehicle agility.

-

Enhanced Lubrication Systems: Integrated lubrication channels reduce friction and wear, prolonging service life.

-

Noise and Vibration Reduction: Optimized gear tooth profiles minimize operational noise, enhancing cabin comfort.

-

Integration with Advanced Driver Assistance Systems (ADAS): Modern steering gears can interact with sensors and electronic control units for lane-keeping assistance, automatic parking, and collision avoidance.

These innovations are driving a shift toward smarter, more reliable steering systems that cater to both traditional and electric vehicles.

Maintenance and Longevity of Steering Gear

Proper maintenance of automobile steering gear is essential for consistent performance. Regular inspection should focus on gear wear, lubrication levels, and alignment. Signs of wear may include unusual steering resistance, vibrations, or noise during operation.

Periodic replacement of worn components and use of high-quality lubricants can extend the lifespan of the steering gear, ensuring reliable steering control and reducing the risk of mechanical failure. Preventive maintenance not only enhances safety but also reduces long-term repair costs.

Steering Gear in Different Vehicle Segments

The application of steering gear systems varies across vehicle types. In compact passenger cars, rack-and-pinion steering gears prioritize responsiveness and light steering feel. Trucks and commercial vehicles often use recirculating ball systems for handling higher loads. Electric and hybrid vehicles increasingly adopt electronically assisted steering gears to improve energy efficiency and enable autonomous driving features.

By adapting the steering gear design to specific vehicle requirements, manufacturers can optimize performance, safety, and driving comfort across different market segments.

Impact of Steering Gear on Vehicle Dynamics

The performance of steering gear significantly influences overall vehicle dynamics. Precise gear meshing ensures accurate wheel angles, which enhances cornering stability, braking response, and straight-line tracking. Poorly manufactured or worn steering gears can result in play, vibration, and reduced control, potentially compromising driver safety.

Advanced steering gear systems, integrated with electronic controls, further contribute to adaptive handling. These systems adjust steering ratios, resistance, and responsiveness based on speed, load, and driving conditions, improving both performance and comfort.

Future Trends in Steering Gear Technology

The future of automobile steering gear points toward greater integration with digital vehicle systems and electric mobility. Trends include:

-

Fully Electric Steering Systems: Eliminating hydraulic components for lighter, more efficient steering.

-

Predictive Steering Adjustments: Using AI and sensor data to anticipate driver actions and adjust steering in real-time.

-

Sustainable Materials: Incorporating lightweight alloys and recyclable metals to reduce environmental impact.

-

Autonomous Vehicle Compatibility: Steering gears designed for fully autonomous vehicles, capable of seamless electronic control without human input.

These developments are reshaping the role of steering gear from a purely mechanical component to a key enabler of smart vehicle systems.

Conclusion

The automobile steering gear remains a cornerstone of vehicle control and safety. From its precision structural design and material selection to its integration with advanced technologies, it ensures that drivers can steer with confidence and vehicles respond reliably to road conditions.

Ongoing innovations in design, materials, and electronic integration are making steering gears more efficient, durable, and adaptable to emerging automotive trends. Understanding the features and functions of steering gear helps industry professionals, engineers, and vehicle enthusiasts appreciate the sophistication behind this seemingly simple yet vital component.

www.lrfgears.com

Longruifa