FFS (Form Fill Seal) bagger is an advanced packing system widely used in the food, pharmaceutical and consumer goods industries to automate the packing process. This machine streamlines operations by forming a package from a flat roll of tubular film, filling it with the desired product and sealing it, all in one continuous process. This machine typically consists of several key components including a film unwinder, a forming station that shapes the film into a bag, a filling mechanism that dispenses the product into the formed package and a sealing unit that securely closes the package to maintain freshness and prevent contamination. These devices can handle various types of products including powders, granules and solids, making them versatile for different applications. Additionally, modern FFS machines are equipped with advanced technology such as sensors and programmable logic controllers (PLC), enabling precise control over the filling and sealing processes.

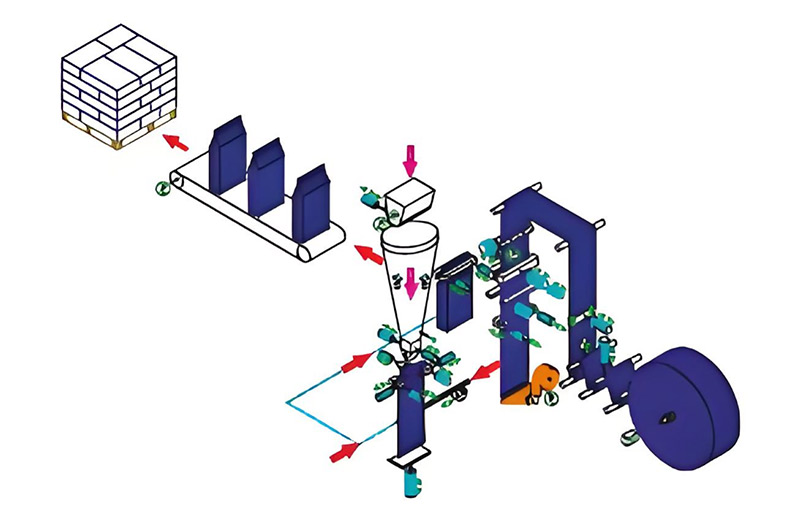

Working Process:

1. Film feeding: The FFS machine starts with a roll of packaging tubular film which is unwound and fed through the machine.

2. Forming: The packaging film is then formed into the desired package shape, such as a pouch or sachet, using a forming collar and a set of forming jaws. The formed package is then held open by the jaws.

3. Filling: The pharmaceutical product is dispensed into the formed package using a filling mechanism such as a volumetric filler, a dosing pump, or a weighing scale.

4. Sealing: Once the package is filled, the sealing process begins. The sealing jaws of the FFS machine come together and apply heat or pressure to the top and bottom of the package, sealing it shut.

5. Cutting: The sealed package is then cut from the film roll using a cutting machine such as a rotary knife or a guillotine.

6. Discharge: The completed package is discharged from the FFS machine for further processing, such as labeling, palletizing, or wrapping.

Product Feature:

1. Increased Efficiency: FFS machines automate the packing process, significantly reducing the time required for packing products compared to manual methods.

2. Cost Reduction: By minimizing labor costs and reducing material waste, these tools contribute to overall cost savings in production.

3. Consistent Quality: The automated process ensures uniform packaging, leading to consistent quality in the final product.

4. Versatility: These machines can handle a wide range of products including powders, granules and solids. This versatility makes them suitable for various industries, adapting to different packing needs effortlessly.

5. Enhanced Product Freshness: The sealing capabilities of these machines help maintain product freshness and prolonged shelf life. By minimizing exposure to air and contaminants, they ensure that products remain in optimum condition until they reach the consumer.

6. Reduced Material Waste: The precision of FFS machines leads to suitable use of packing materials which reduces waste. Lower material consumption not only cuts costs but also supports sustainability efforts.

7. Easy Integration: These devices can be easily integrated into existing production lines. This flexibility provides a smooth transition to automated packing solutions without major disruptions to ongoing operations.

www.dostar-pack.com

Dostar Packing