The electronics sector is rapidly moving toward smaller, lighter, and smarter devices, all while demanding higher performance and reliability. To achieve this balance, engineers are increasingly relying on flexible circuit technology. The flex PCB board has emerged as a cornerstone of this evolution, allowing circuits to bend, fold, and withstand motion without compromising functionality. This article explores the essential advantages of flex PCB boards and highlights their diverse applications across industries ranging from automotive to aerospace and healthcare.

Key Advantages of Flex PCB Boards

1. Thin, Lightweight, and Space-Saving

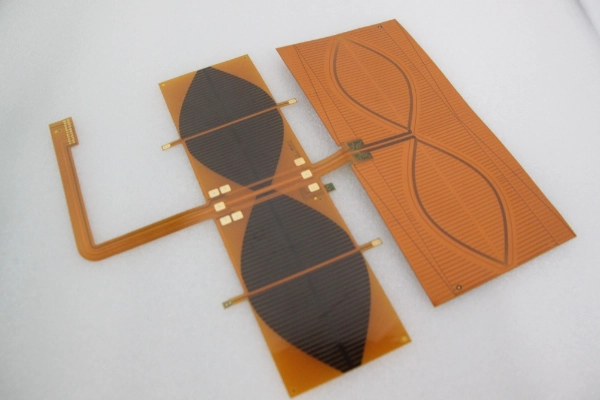

Flex PCB boards stand out because of their ultra-thin construction—some as slim as 0.05 mm, with layer counts from 1 to 6. This makes them ideal for compact products like smartphones, wearable devices, and medical instruments. By reducing the need for bulky wiring harnesses and connectors, they streamline assembly processes and minimize overall system weight, a critical factor in modern miniaturized designs.

2. Designed for Continuous Motion

Unlike rigid PCBs, a flex PCB board is engineered to endure constant folding, bending, and repetitive motion cycles. Whether in foldable smartphones, robotic arms, or aerospace modules, flex PCBs provide long-lasting electrical stability under mechanical stress. This makes them indispensable for products where dynamic movement is part of everyday operation.

3. Superior Thermal Performance and Reliability

Effective heat management is crucial for device stability. Flex PCB boards are optimized for excellent thermal dissipation, ensuring dependable operation even in high-temperature or confined spaces. In automotive dashboards exposed to both sunlight and prolonged system use, these boards maintain electrical performance and resist degradation—delivering the reliability required for safety-critical and industrial-grade applications.

Real-World Applications of Flex PCB Boards

Automotive Systems

Flex PCB boards enable modern vehicles to integrate sleek, digital dashboards and multifunctional instrument panels. Their resilience to vibration, heat, and stress makes them highly suitable for harsh automotive conditions. Additionally, the lightweight design contributes to better fuel efficiency and extended electric vehicle range.

Aerospace and Satellites

Weight and reliability are paramount in aerospace. Flex PCB boards reduce dependence on heavy wiring harnesses, withstand the intense vibration of rocket launches, and perform consistently under extreme temperature variations in orbit. From communication payloads to navigation systems, they are key to next-generation space technology.

Medical and Wearable Devices

Healthcare technologies demand compact, lightweight, and ergonomic solutions. Flex PCB boards support advanced applications such as implantable sensors, diagnostic probes, and patient monitoring systems. Their ability to endure sterilization cycles and mechanical stress makes them well-suited for critical medical environments.

Industrial Robotics and IoT

In robotics and IoT devices, durability and adaptability are essential. Flex PCB boards simplify wiring in robotic joints, reduce failure points under vibration, and allow compact sensor integration in IoT nodes. The result is higher system uptime, reduced maintenance, and more efficient industrial automation.

Why Flex PCB Boards Are the Industry's Choice

Flex PCB boards have become a preferred solution because they combine cutting-edge engineering with practical adaptability. They can be manufactured with copper thicknesses ranging from 8 μm to 70 μm, board sizes up to 250 mm × 610 mm, and multiple surface finishes such as ENIG, OSP, and gold fingers. This level of customization ensures compatibility across a wide range of projects.

For companies scaling from prototypes to full production, flex PCB boards deliver consistency, performance, and reliability, making them indispensable in today's competitive electronics landscape.

Conclusion

The growing demand for smaller, lighter, and smarter electronics has positioned the flex PCB board as a vital technology for the future. Its ability to combine flexibility, durability, and thermal reliability allows it to serve critical roles in automotive systems, aerospace missions, healthcare devices, and industrial automation.

By enabling engineers to design electronics that are both compact and high-performance, flex PCB boards are not only meeting today's challenges but also paving the way for tomorrow's innovations.

https://www.sprintpcb.net/pcb/Flexible-PCB.html

www.sprintpcb.net

SprintPCB