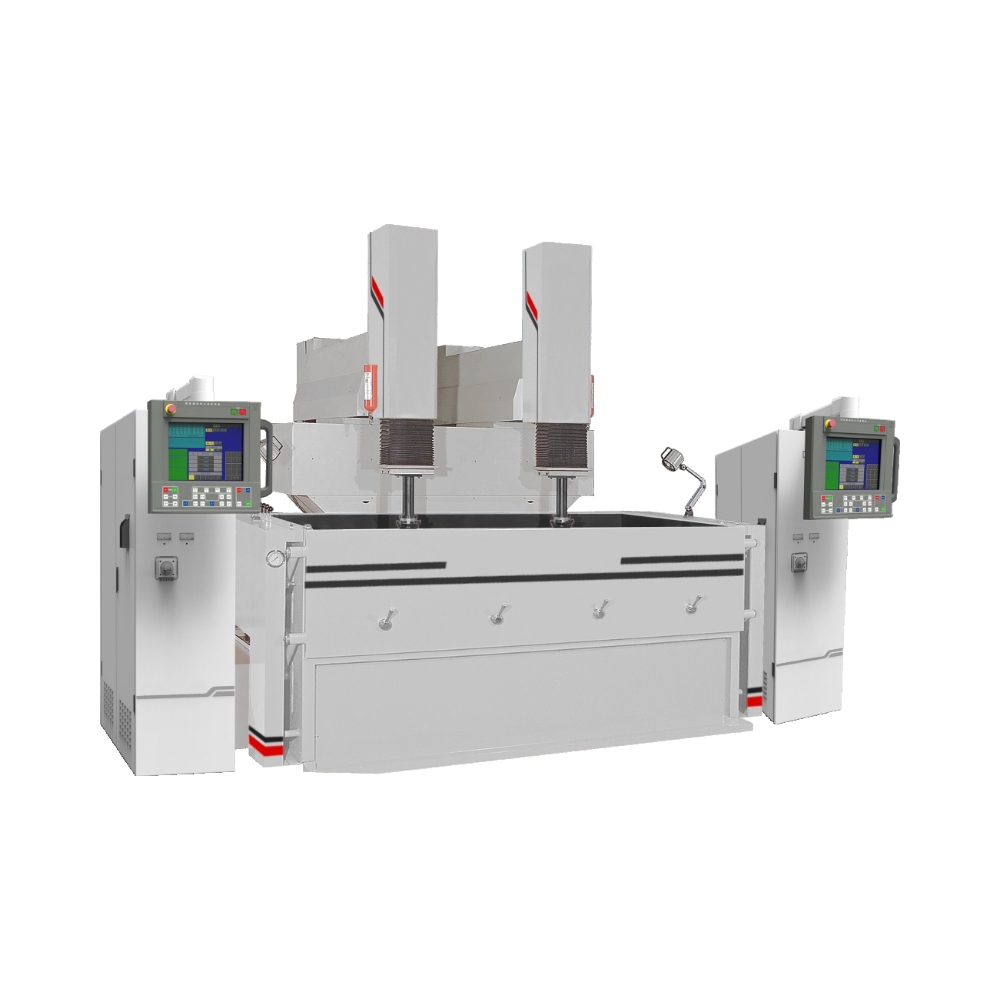

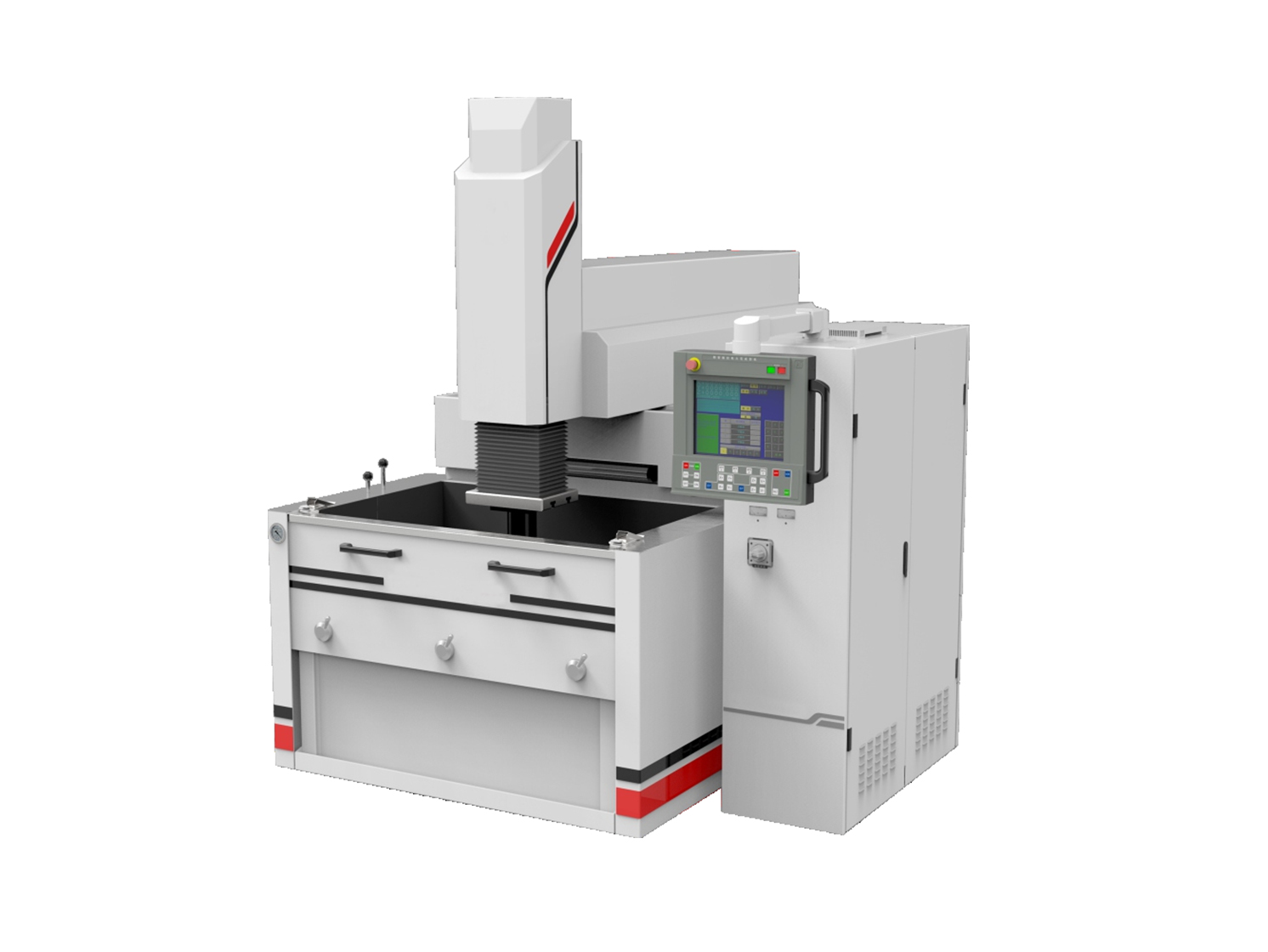

In industries where precision, surface quality, and manufacturing consistency are essential, the mirror spark EDM machine has become a preferred solution. Its ability to achieve ultra-smooth finishes, highly accurate details, and stable machining performance makes it ideal for molds, precision components, and complex metal parts. In this article, we explore the advantages of mirror spark EDM technology and introduce Suzhou Zhiquan Electromechanical Equipment Co., Ltd., a reputable enterprise specializing in CNC machining centers, wire cutting machines, EDM machines, and milling machines.

Understanding the Value of Mirror Spark EDM Technology

Mirror spark EDM machines are engineered to deliver exceptional surface finishes comparable to mirror polishing. By using controlled electrical discharge, these machines remove material without mechanical force, allowing the machining of extremely hard metals, intricate shapes, and delicate structures.

This technology is especially valued in mold manufacturing, precision tooling, and high-end metal processing, where accuracy, smoothness, and repeatability are crucial.

Benefits of High-Precision EDM Machining

Mirror spark EDM machines offer several advantages that set them apart from conventional machining methods:

Superior Surface Smoothness

The defining feature of a mirror spark EDM machine is its ability to produce highly reflective, ultra-fine surfaces. This minimizes the need for manual polishing, saving time and reducing labor costs. The smoother surface also enhances mold performance and extends product lifespan.

Exceptional Dimensional Accuracy

A high-quality EDM machine ensures stable discharge control, precise pulse generation, and consistent machining depth. These factors allow users to achieve:

-

Sharp edges

-

Micro-level detail

-

Tight tolerances

-

Repeatable accuracy

Manufacturers like Suzhou Zhiquan Electromechanical Equipment Co., Ltd. design EDM systems with advanced control algorithms and durable electronic components to ensure reliable, high-precision performance.

Capability to Process Hard and Complex Materials

Mirror spark EDM technology excels where traditional cutting tools struggle. It can machine ultra-hard steels, carbide materials, and heat-treated components without deformation or tool wear. This makes it ideal for industries requiring complex cavities, deep slots, and narrow ribs.

Stable and Efficient Machining Performance

Modern mirror spark EDM machines include intelligent monitoring systems, temperature-compensated structures, and energy-efficient discharge modules. These features improve machining stability, reduce electrode wear, and optimize power usage—resulting in both cost efficiency and production reliability.

Applications in High-Precision Industries

The versatility of mirror spark EDM machines makes them suitable for various industries, including:

-

Mold manufacturing for injection molding, die casting, and rubber molds

-

Aerospace and defense components requiring tight tolerances

-

Automotive precision parts and engine components

-

Medical device production with delicate geometries

-

Electronics and semiconductor tooling

Each of these fields demands machines that deliver consistent, smooth, and accurate machining results—qualities at which mirror spark EDM systems excel.

Why Work with Suzhou Zhiquan Electromechanical Equipment Co., Ltd.

As an enterprise specializing in CNC machining centers, wire cutting machines, EDM equipment, and milling machines, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. is known for its strong engineering capability and reliable machinery performance. Their mirror spark EDM machines are designed to be:

-

High-precision, ensuring refined surface finishes and accurate geometries

-

Stable and durable, built with wear-resistant components and robust mechanical structures

-

Efficient and intelligent, equipped with advanced control systems for smooth operation

-

Versatile, suitable for a wide range of industrial machining needs

-

User-friendly, featuring intuitive interfaces and easy maintenance

With a commitment to innovation, professional manufacturing standards, and attentive customer service, the company continues to support global manufacturers seeking advanced, high-performance machining solutions.

Conclusion

Choosing a mirror spark EDM machine is a strategic decision for businesses that value accuracy, superior surface quality, and reliable machining performance. Whether you work in mold making, metal processing, or precision engineering, this technology ensures higher productivity, improved product quality, and long-term operational benefits.

Backed by strong technical expertise and comprehensive machinery solutions, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. remains a trusted partner for industries pursuing refined, efficient, and highly precise manufacturing capabilities.

A well-designed mirror spark EDM machine is more than just equipment—it is an investment in craftsmanship, performance, and future competitiveness.

Electrical Discharge Machining Solutions for Precision Metalworking

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.