When it comes to designing and operating a safe, efficient, and compliant incineration system, every component matters — and the air duct is no exception. Often overlooked, the incinerator air duct plays a critical role in maintaining airflow, temperature control, and emission management. Selecting the right type of ductwork for your incineration facility can directly affect the system’s performance, energy efficiency, and environmental compliance.

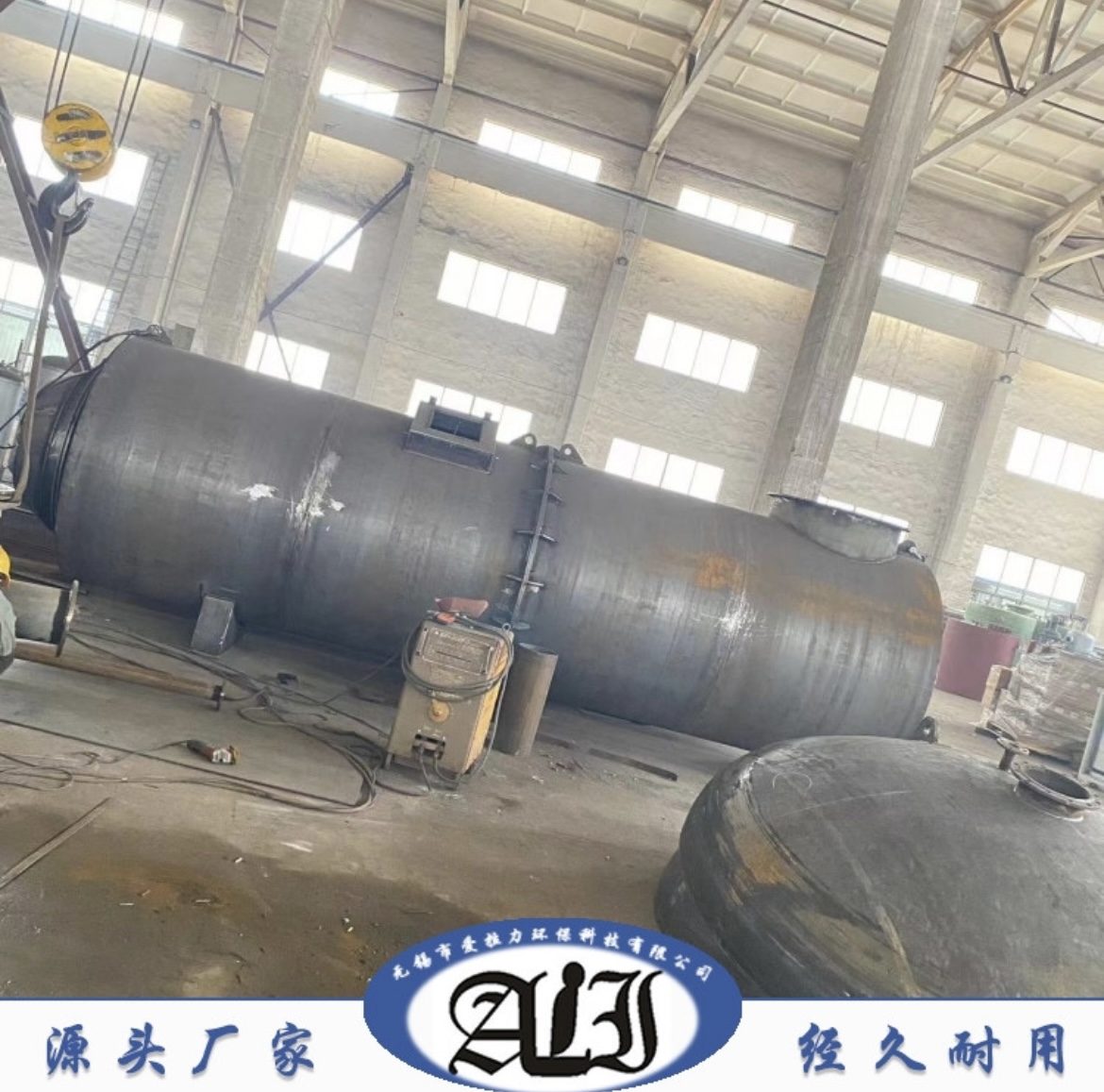

At Airali Environmental Protection Technology, we specialize in the design, manufacturing, and installation of advanced incineration systems and pollution control equipment. Drawing on our experience in treating hazardous waste, organic exhaust gases, and industrial byproducts, this guide will walk you through key considerations when choosing the best incinerator air duct for your facility.

1. Understand the Role of the Air Duct in Incineration Systems

In incineration processes, air ducts are responsible for delivering combustion air, managing airflow patterns, and controlling exhaust gas pathways. Proper air duct design helps maintain optimal combustion temperatures, reduce emissions, and protect downstream equipment from heat or chemical damage.

2. Consider the Type of Waste Being Treated

Different waste streams — such as organic solvents, medical waste, or chemical sludges — produce varying exhaust compositions and temperatures. This significantly impacts the air duct’s required material strength, corrosion resistance, and insulation.

Airali Environmental Protection Technology offers ductwork solutions tailored to specific incineration systems, including:

-

Solid Waste Incinerators

-

Medical Waste Pyrolysis Furnaces

-

Rotary Kiln Incinerators

-

Regenerative Thermal Oxidizers (RTOs)

-

Catalytic Incinerators

-

Liquid Waste Incinerators

By aligning duct specifications with the waste type, facilities can ensure safe and durable operation.

3. Choose the Right Materials for Durability and Safety

The air duct must withstand high temperatures, corrosive gases, and pressure variations. Common materials include:

-

Stainless Steel (304/316): Ideal for high-corrosion environments

-

Inconel or Hastelloy: Suitable for extreme temperatures and chemical exposure

-

Carbon Steel with Lining: Cost-effective for less aggressive applications

For high-performance incinerators, Airali recommends using multi-layered ducts with thermal insulation and anti-corrosion coatings to extend service life and reduce maintenance frequency.

4. Ensure Proper Sizing and Layout

Undersized or poorly routed ducts can lead to pressure drops, backflow issues, or incomplete combustion. A properly sized and laid-out air duct system improves:

-

Air distribution balance

-

System efficiency

-

Heat recovery potential

-

Emission control effectiveness

Airali’s engineering team uses simulation and modeling tools to design duct systems with optimal flow rates, minimal resistance, and effective heat transfer.

5. Factor in Thermal Expansion and Vibration

Incineration systems operate at high temperatures that cause ducts to expand. Without proper expansion joints or flexible connectors, thermal stress can lead to cracking or structural failure. Likewise, vibration from fans or burners needs to be absorbed to avoid fatigue damage.

Tip: Choose duct designs that incorporate expansion bellows, vibration dampers, and thermal movement allowances, which Airali includes as standard in all high-temperature duct systems.

6. Plan for Maintenance and Monitoring

Good air duct design should also consider accessibility for inspection and cleaning. Incorporating inspection ports, removable sections, and condition monitoring sensors makes it easier to keep the system running efficiently and safely.

Why Choose Airali Environmental Protection Technology?

Airali Environmental Protection Technology is a high-tech environmental enterprise that integrates design, production, installation, and commissioning of waste incineration and pollution control equipment. With a focus on industrial waste gas, liquid, and hazardous waste treatment, we deliver:

-

Customized incineration systems for diverse industrial sectors

-

Full engineering support, from concept to commissioning

-

Advanced materials and smart system integration

-

Compliance with national and international environmental standards

Our expertise ensures that every component, including air ducts, is optimized for performance, durability, and sustainability.

Conclusion

Choosing the right incinerator air duct is not just about material and size — it’s about ensuring safety, longevity, and environmental compliance. Whether you're upgrading an existing facility or building a new one, partnering with experienced experts like Airali Environmental Protection Technology will help you make informed decisions that add long-term value to your operations.

www.wxallhb.com

Wuxi Ailali Environmental Protection Technology Co., Ltd.