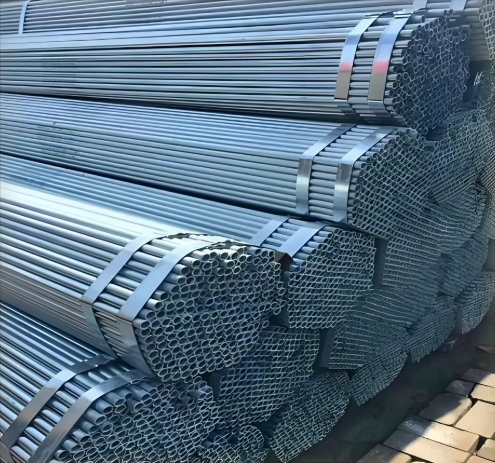

The demand for robust, durable, and cost-effective materials in infrastructure development continues to grow as urbanization and industrialization advance globally. Among the many materials used, galvanized steel pipes have emerged as a preferred choice for a wide range of infrastructure projects. Their combination of strength, corrosion resistance, and long service life makes them indispensable in water supply systems, structural applications, energy transportation, and construction frameworks.

Guangqi, a reputable manufacturer specializing in the production and sale of galvanized steel pipes, galvanized steel-plastic composite pipes, coated pipes, galvanized square and rectangular pipes, and ductile iron pipes, provides high-quality solutions that meet the evolving requirements of modern infrastructure projects. Their products are designed to withstand demanding conditions while offering superior performance, making them a key partner for builders, contractors, and industrial developers.

Role of Galvanized Steel Pipes in Modern Infrastructure

Galvanized steel pipes serve as critical components in infrastructure due to their ability to resist rust and corrosion, which are common challenges in outdoor and industrial environments. The galvanization process, which involves coating steel pipes with a layer of zinc, creates a protective barrier that prevents environmental elements from degrading the steel.

These pipes are widely used in water distribution networks, scaffolding, road construction, railways, bridges, and industrial pipelines. Their durability ensures that infrastructure projects maintain their integrity over time, reducing the frequency of maintenance and replacements.

Key Advantages of High-Grade Galvanized Steel Pipes

High-grade galvanized steel pipes offer a range of benefits that make them a superior choice for infrastructure applications. These include:

Exceptional corrosion resistance due to the protective zinc layer.

Long service life, even in harsh weather and industrial conditions.

Cost-effectiveness by minimizing long-term maintenance expenses.

Versatility for various infrastructure uses, including underground, overhead, and exposed installations.

Compatibility with modern construction techniques and welding processes.

Guangqi’s high-grade galvanized pipes undergo stringent quality control and advanced manufacturing processes to ensure they meet international standards for strength and performance.

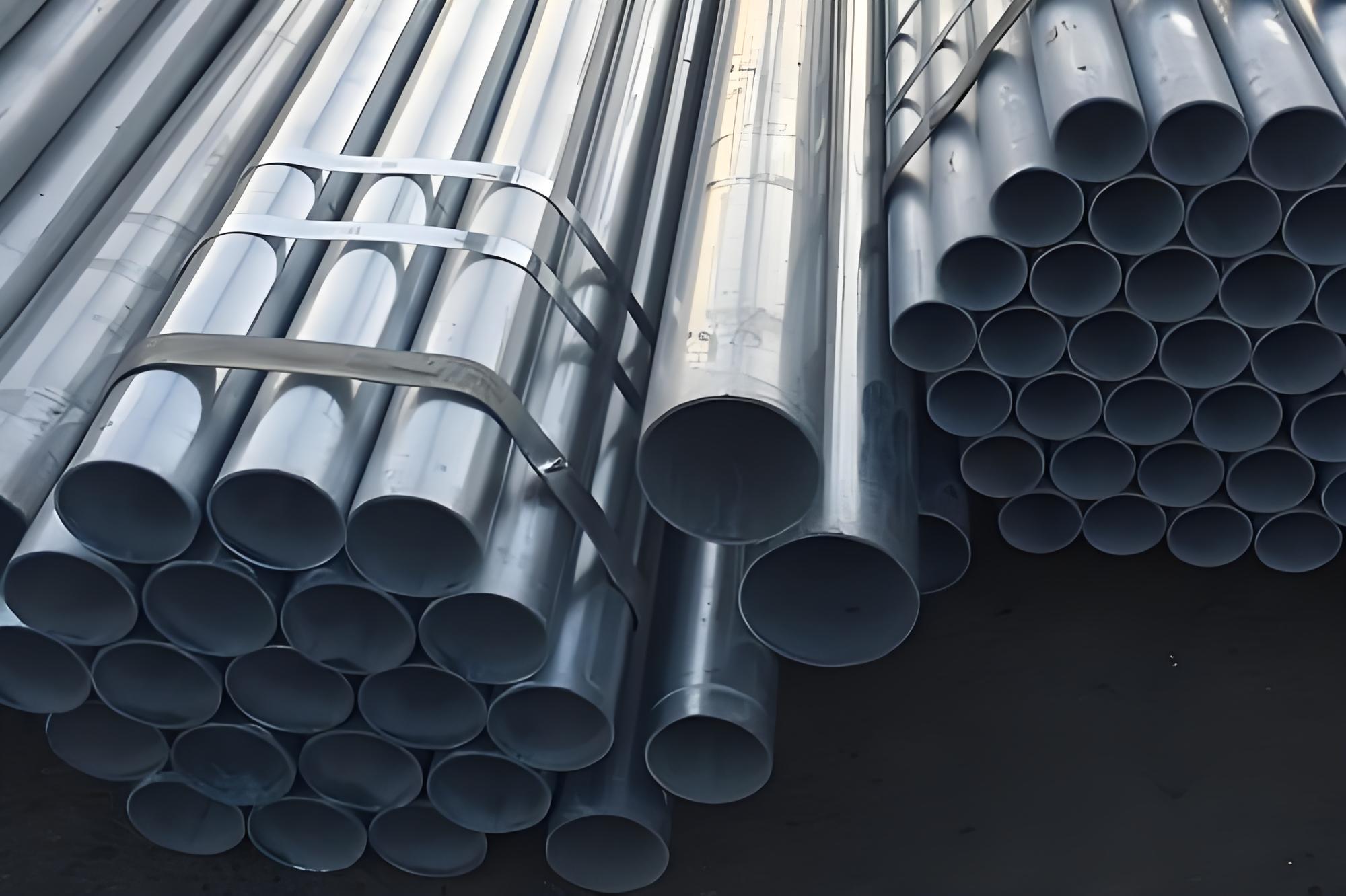

Structural Strength and Load-Bearing Capabilities

One of the significant advantages of galvanized steel pipes is their impressive structural strength. These pipes can handle substantial loads without deformation, making them ideal for use in construction frameworks, building supports, and heavy-duty scaffolding systems.

Their ability to withstand mechanical stress also makes them a reliable option for industrial applications, where pressure, vibration, and dynamic forces are common.

Corrosion Resistance for Long-Term Reliability

Corrosion is one of the leading causes of pipe degradation in infrastructure projects. High-grade galvanized pipes provide long-term resistance to rust and chemical wear due to their zinc coating, which acts as a sacrificial layer, preventing the underlying steel from corroding.

This makes them particularly suitable for outdoor installations, underground pipelines, and environments exposed to moisture, humidity, and pollutants.

Cost Efficiency and Low Maintenance Requirements

Galvanized steel pipes offer a favorable cost-to-performance ratio. While the initial investment may be slightly higher than some uncoated steel alternatives, the long-term savings are significant due to reduced maintenance, fewer replacements, and minimized downtime for repairs.

Guangqi’s commitment to producing durable pipes ensures clients benefit from lower lifecycle costs, making their products a smart investment for large-scale infrastructure developments.

Versatility in Applications

The adaptability of galvanized steel pipes extends across multiple sectors. They are commonly used in water supply and drainage systems, gas pipelines, greenhouse structures, highway guardrails, and construction frameworks.

Their compatibility with modern installation methods and ease of integration with fittings, connectors, and welding techniques make them a flexible choice for engineers and contractors.

Environmental and Sustainability Benefits

As sustainability becomes an increasingly critical factor in infrastructure development, galvanized steel pipes offer notable advantages. Galvanization extends the life of steel, reducing the need for frequent replacements and conserving resources. Moreover, steel is highly recyclable, ensuring that end-of-life pipes can be repurposed without contributing to environmental waste.

Guangqi actively implements eco-friendly production techniques, using energy-efficient processes and recyclable materials in its manufacturing operations.

Ease of Inspection and Predictable Performance

Another benefit of using galvanized steel pipes is their ease of inspection and predictable degradation pattern. Unlike some materials that deteriorate without warning, galvanized coatings provide visible signs of wear, making it easier to plan maintenance schedules before critical failures occur.

Safety and Reliability in Critical Infrastructure

In applications where safety is paramount—such as bridges, highways, and industrial facilities—high-grade galvanized pipes provide unmatched reliability. Their consistent performance under variable conditions ensures that essential infrastructure operates without unexpected interruptions.

Contribution to Aesthetic and Structural Integrity

Apart from their functional benefits, galvanized steel pipes also contribute to the visual appeal and structural cohesion of projects. Their smooth, metallic finish adds a polished look to exposed installations, while their rigidity supports clean, stable construction lines.

Technological Advancements in Galvanized Pipe Manufacturing

Advancements in manufacturing technologies have further enhanced the quality and performance of galvanized pipes. Modern galvanization techniques ensure uniform coating, improved adhesion, and enhanced resistance to scratches and abrasions.

Guangqi leverages cutting-edge galvanizing processes, strict quality inspections, and continuous innovation to deliver products that exceed industry benchmarks.

Integration with Modern Infrastructure Systems

As infrastructure projects increasingly adopt smart technologies and advanced construction methodologies, galvanized steel pipes remain compatible with these developments. Their strength, durability, and modular compatibility make them suitable for integration with smart city infrastructure, energy-efficient systems, and large-scale industrial automation.

Maintenance Practices to Prolong Service Life

While galvanized pipes are known for their longevity, proper maintenance practices can further extend their service life. Regular inspections, protective coatings in highly corrosive areas, and adherence to proper installation techniques help maximize their performance.

Guangqi offers expert guidance on maintenance and installation best practices, ensuring that clients achieve optimal results from their infrastructure investments.

Future Prospects of Galvanized Steel Pipes in Infrastructure

The future of galvanized steel pipes looks promising as global infrastructure demands continue to rise. With advancements in zinc coating technologies and the push toward sustainable construction, their role in building resilient cities and industrial facilities is expected to grow.

Guangqi remains committed to innovation, ensuring its galvanized steel pipes stay at the forefront of market needs while supporting the global shift toward more durable and sustainable infrastructure solutions.

Conclusion

High-grade galvanized steel pipes offer a unique combination of strength, durability, and cost-effectiveness, making them a cornerstone of modern infrastructure development. Their ability to resist corrosion, support heavy loads, and integrate seamlessly into diverse applications makes them an indispensable choice for engineers and project developers.

Guangqi, as a trusted manufacturer of galvanized steel pipes, galvanized steel-plastic composite pipes, coated pipes, galvanized square and rectangular pipes, and ductile iron pipes, continues to provide reliable and innovative solutions that meet the challenges of today’s infrastructure projects.

By selecting high-grade galvanized pipes and following best practices for installation and maintenance, project owners can achieve long-term performance, reduced costs, and sustainable growth in their infrastructure endeavors.

The Role of Galvanized Steel Pipes in Modern Infrastructure and Water Supply Systems

www.gqsteelpipe.com

Foshan Nanhai Guangqi Steel Industry Co., Ltd.